5MWe Biomass Boiler and fluidised bed fabricated and tested by CF Struthers. Carbon steel, refractory lined casing, circular radiant coil fabricated in 2” boiler tube using our in-house manufacturing technology.

‘World first’ Circular Economiser Coil together with Evaporator section.

Complete package pre-fabricated at our Millennium Works in Hull, transported to site and assembled/installed together with access structure, balance of plant, pumps, fans, bag filters and process pipework.

Large Scale Biomass, Waste to Energy steam packages and associated equipment

The first pass radiant chamber (inner coil) continuously formed 2” Schedule 80 carbon steel boiler tube, helical coil. Constructed strictly in accordance with ASME rules and regulations. All welds 100% radiography and complete coil module hydrotested prior to shipping. The coil conforms to PED regulations with an operating pressure of 70BarG.

The internal surface of the coil has 1800 welded anchors to facilitate the site installation of refractories.

The radiant chamber second pass (annulus between inner & outer coils) is formed as per the inner coil but for an overall diameter of 5m.

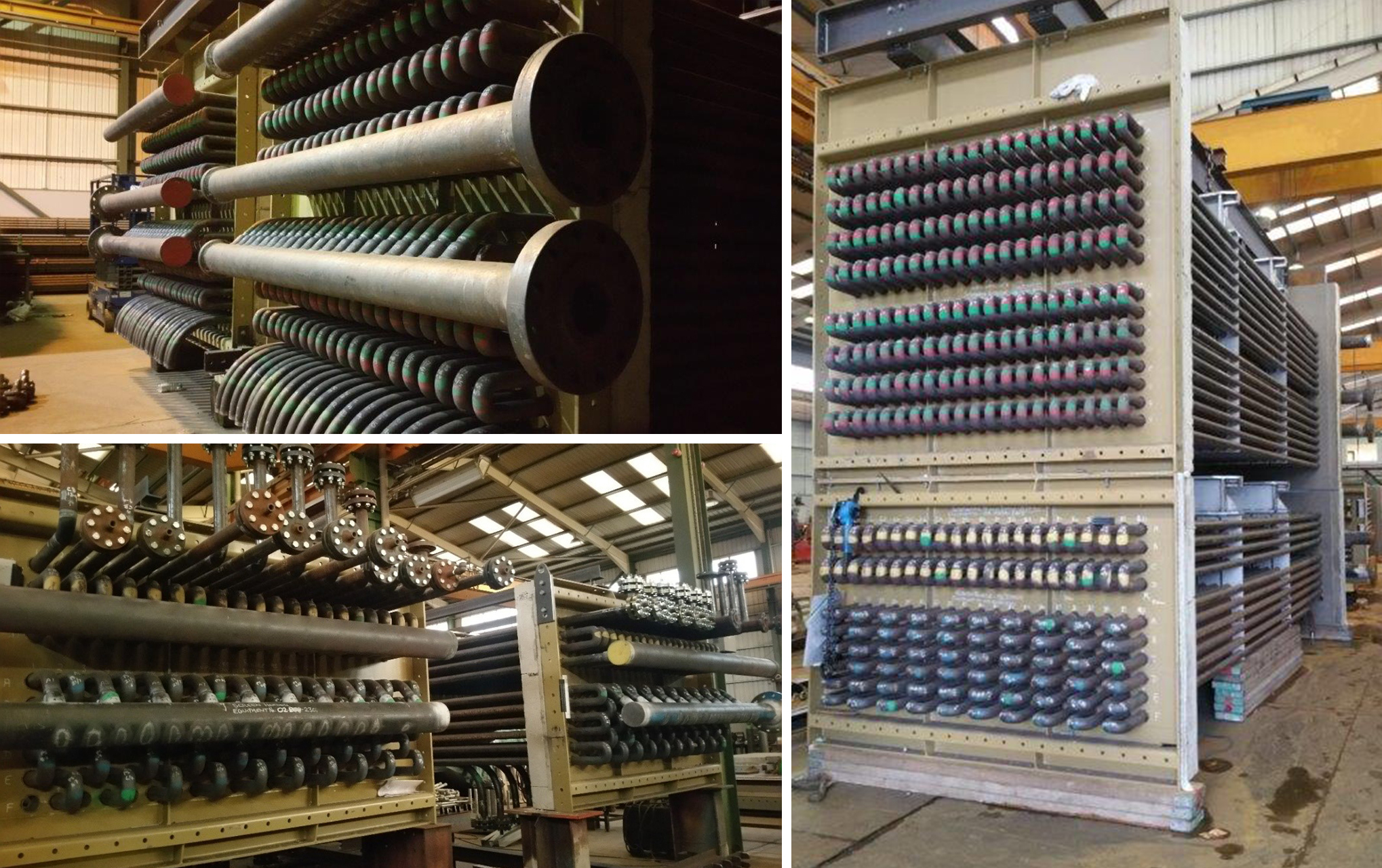

Typical convection sections of steam boiler (40te/hour). Conventional construction in serpentine configuration held with conventional tube sheet support arrangement. The boiler modules are designed and constructed in strict accordance with ASME rules and regulations. Modules including casings pre-refractory lined to achieve external temperature of the carbon steel finished painted casing of 60oC. These boiler modules are subject to radiography and hydro test prior to shipping. Shipping weights approx. 85te per module.

Images: The convective boiler modules – Serpentine tube banks – fixed end tube sheets (insulated). Ready for assembly with pre-insulated (refractory) side casing walls.

Images Above: One of two Fluidised Bed and 40te/hr, 65Barg, 480oC steam Boiler Packages and typical client visit during advanced stage of construction and commissioning of the plant.